Hawker Hurricane Kit

£34.99

DESCRIPTION

At a Glance

- Power System – Rubber Free Flight

- Wingspan – 18″ (460mm)

- Approximate AUW – 25g

- Difficulty – Beginner

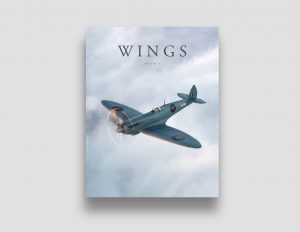

HAWKER HURRICANE – THE UNSUNG HERO

The Hawker Hurricane was designed by Sydney Camm of the Hawker Aircraft Company to comply with specifications issued by the British government as it reacted to the re-armament of the German Luftwaffe prior to World War 2. The other aircraft designed to meet these specifications was the more famous, and arguably more glamorous, Supermarine Spitfire. Both aircraft used the now legendary Rolls Royce Merlin engine, but had little else in common.

Unlike the complicated Spitfire, the much larger Hurricane used basic and established production techniques that made them simple and relatively cheap to manufacture, as well as making them easier to repair by ground crew in the field. Although the faster more elegant Spitfire took more of the plaudits, the Hurricane was the workhorse and in truth it downed more enemy aircraft in total than the Spitfire.

In the fight against Luftwaffe bombing raids on Britain the two planes were an effective combination with the Spitfires attacking the fighter escort and the Hurricanes attacking the bombers themselves. Over 14,500 Hurricanes had been manufactured at the Hawker Aircraft Company and in shadow factories in the UK and Canada by the time production ceased in 1944.

YOUR KIT

This kit is designed for you to build a traditionally constructed, rubber powered, free flight model of a Hawker Hurricane. The kit includes the materials (other than paints) to complete the suggested authentic scheme of a red Hurricane that served in the 527 Calibration Squadron, which flew from Castle Camps, Cambridgeshire in 1943.

This is a simple but striking scheme, but you can decide to do your own favourite or more complicated scheme if you wish. Construction of the model from this kit uses the traditional method of “stick and tissue”, that consists of a built up balsa wood skeleton (framework), covered with a tissue skin. The balsa frameworks are built over a plan that is printed at the exact scale of the model, which is in essence a real engineering drawing. Power is provided by rubber strip motor that is wound up before flight.

Free flight means just that – once the model is launched, it is on its own. It must follow a predetermined flight path established when the model is initially adjusted for flight or “trimmed”. This type of traditional building technique and flying requires a degree of patience and skill, but is extremely rewarding.

Typically for a small model and in the spirit of the traditional kits, profiles are simplified and adjusted from the original and a relatively large propeller is used. This is done so that the model is light and stable enough to fly on its own, is simple in construction and can work with the rubber motor. These adjustments have been done with care and sensitivity so that the shape and spirit of the original aircraft is preserved as much as possible. Also in the spirit of the traditional kits, additional items required to build the model are things that can be found in the kitchen drawer or are easily available on the high street.

KIT CONTENTS

Three balsa sheets with precise laser cut parts and strip wood.

PVA glue for building the wooden frames.

One 150mm diameter plastic propeller.

One pre-bent motor hook and shaft.

Three low friction plastic nose bushings – one for the propeller and two for the undercarriage wheels.

One vacuum formed canopy and spinner.

Piano wire for the main undercarriage and tail wheel legs.

One motor peg (cocktail stick or toothpick). Rubber motor strip.

Tissue to cover the model.

Parts reference sheet (W), full size summary plan sheet (X), scheme diagram sheet (Y) and scheme markings (Z) printed on lightweight paper.

2 in stock (can be backordered)